Transform your engine’s performance with revolutionary sequential turbocharging technology. The Hlava STM is the first and only universally compatible sequential turbocharging manifold, protected by 2 US utility patents.

Universal compatibility with any internal combustion engine designed for forced induction

Optimize turbocharger performance removing turbocharger lag while maintaining turbocharger engagement throughout your power band

Extend turbocharger and engine lifespan through efficiency

Improve your fuel economy

Reduce your emissions footprint

How Sequential Turbocharging Works: The Hlava STM uses two different frame size turbochargers that operate in perfect sequence based on engine load conditions:

○ Provides instant throttle response

○ Handles low-medium load, efficient operation

○ Eliminates traditional turbo lag

○ Optimizes fuel consumption during normal driving

○ Delivers high-end power under increased load

○ Maintains efficiency at high RPM

○ Provides seamless power transition

○ Maximizes performance potential

Our patented dual inline full-flow bypass valves are the heart of the Hlava STM’s performance. These valves automatically regulate exhaust gas flow between turbochargers based on the actuator spring pressure rating of your choosing through:

○ Exhaust Manifold Pressure

○ Turbocharger Speed Requirements

○ Optimal Gas Temperature Management

Traditional turbocharging systems require wastegates to prevent boost-spike conditions. The Hlava STM’s intelligent bypass valve system maintains optimal exhaust manifold pressure, eliminating the need for wastegates entirely.

DISCLAIMER: If you ABSOLUTELY do not want to exceed a specific boost pressure, even if the turbocharger efficiently allows it per its compressor MAP, you’ll want to use a wastegate or, at the very least, ensure your ECU is tuned with a fail-safe to prevent it.

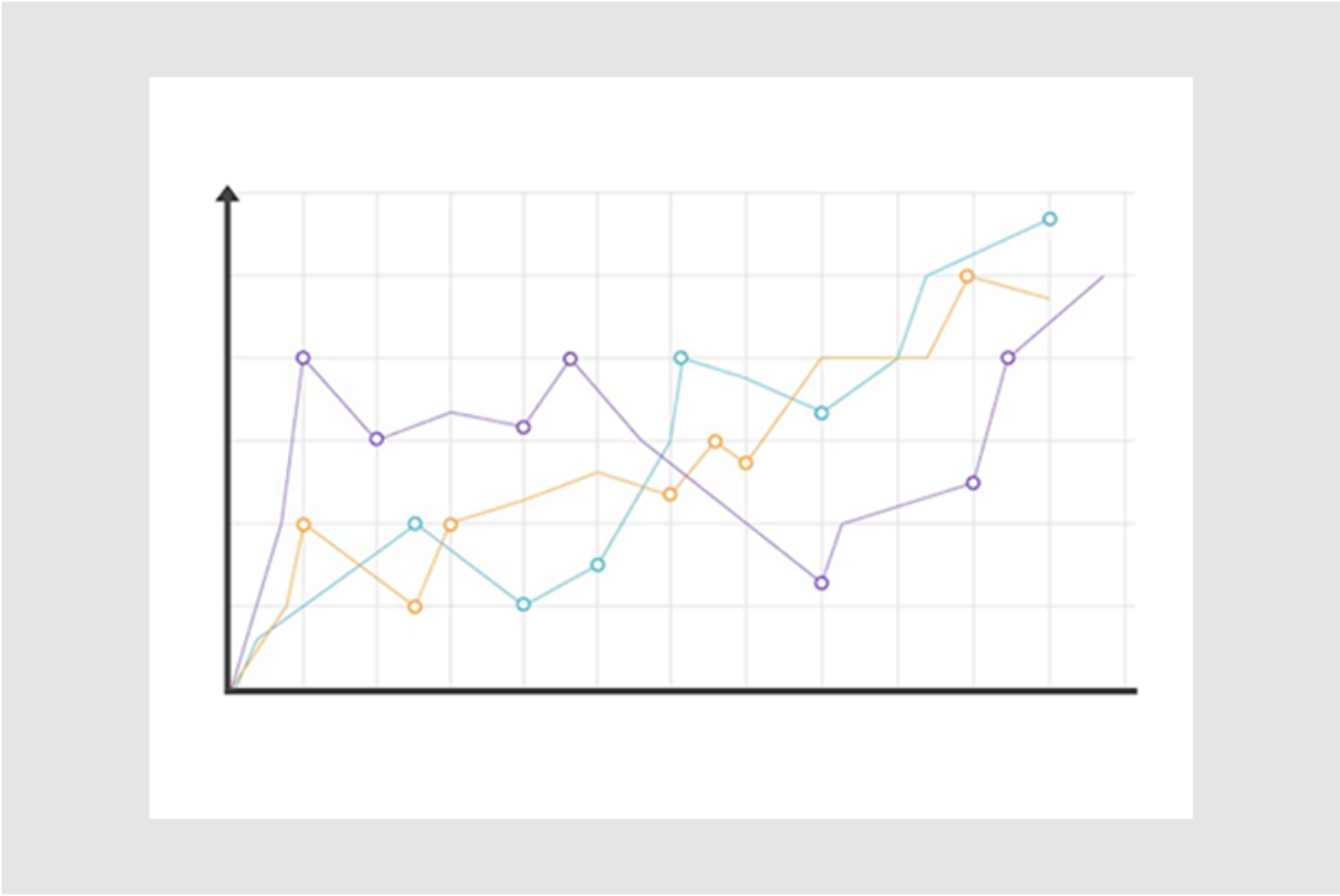

Proven Performance Data: Our latest testing configuration demonstrates the Hlava STM’s adaptability and performance:

○ Primary Turbo: GTX2860R Gen2 (upgraded from GT2554R)

○ Secondary Turbo: G35-1050 Reverse Rotation 1.21 A/R housing (Upgraded from G30-900)

○ Test Engine: 3.1L V6 forced induction

○ Configuration: Left-side orientation

○ Synchronized turbocharger operation achieved

○ No over-revving of primary turbocharger

○ Seamless power delivery from idle to redline

○ Improved fuel economy across all driving conditions

○ Reduced exhaust manifold pressure vs. traditional systems

The Hlava STM installation is actually simpler than traditional turbocharging systems in many cases:

○ No wastegate installation required

○ Standard exhaust manifold mounting

○ Detailed installation documentation provided

○ Direct support from inventor Andrew Hlava

○ Email technical assistance

○ Installation guidance and troubleshooting

The Hlava STM is protected by 2 US utility patents, making it the only sequential turbocharging manifold of its kind available anywhere in the world.

○ Exclusive technology unavailable elsewhere

○ Proven intellectual property protection

○ Investment in genuine innovation

○ Future-proof performance solution

Traditional turbocharging forces compromise between response and power. The Hlava STM eliminates this compromise by using the optimal turbocharger for each operating condition.

○ Smaller primary turbo handles efficient low-load operation

○ Larger secondary turbo only engages when needed

○ Optimized combustion across all RPM ranges

○ Reduced pumping losses vs. traditional systems

○ More complete combustion at all engine loads

○ Optimized air-fuel ratios across RPM band

○ Reduced exhaust manifold pressure

○ Lower exhaust gas temperatures

○ Reduced stress on engine components

○ Lower exhaust manifold pressure

○ Optimized thermal management

○ Extended turbocharger lifespan

○ Project cars and custom builds

○ Race car applications

○ Street performance vehicles

○ Drag racing and road racing

○ Light commercial vehicles

○ Heavy-duty commercial trucks

○ Fleet vehicle optimization

○ Performance commercial applications

○ Boat and marine engine systems

○ Commercial marine vessels

○ Performance marine applications

○ Fuel efficiency optimization

○ Construction equipment

○ Agricultural machinery

○ Generator systems

○ Industrial engine applications

A: Compound turbocharging uses turbos in series all the time. Sequential turbocharging uses different turbos based on load conditions, providing better efficiency and response.

Any turbochargers can be used. We recommend pairing a smaller primary turbo (for response) with a larger secondary turbo (for power).

Basic boost control adjustments may be needed, but the Hlava STM works with existing engine management systems.

Contact us directly at info@hlavastm.com for warranty information and coverage details.

Yes! The Hlava STM is universally compatible with any forced induction internal combustion engine.

Join the first wave of builds and see the results for yourself.